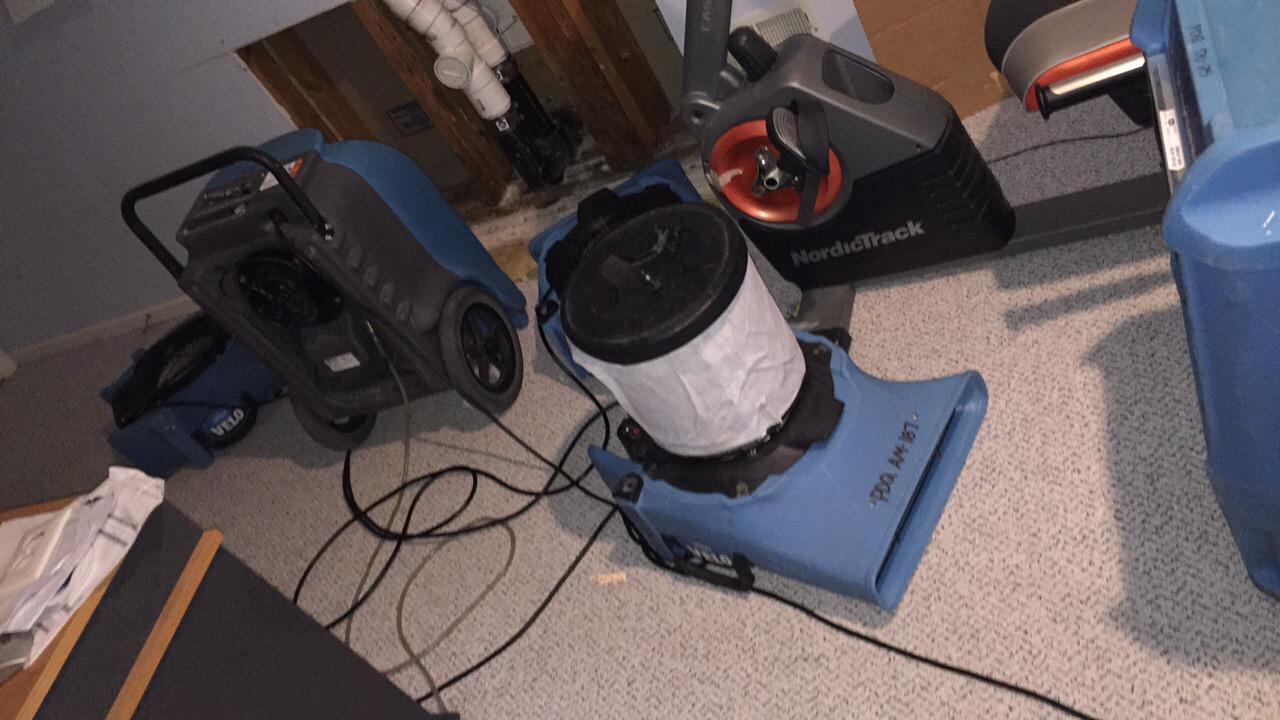

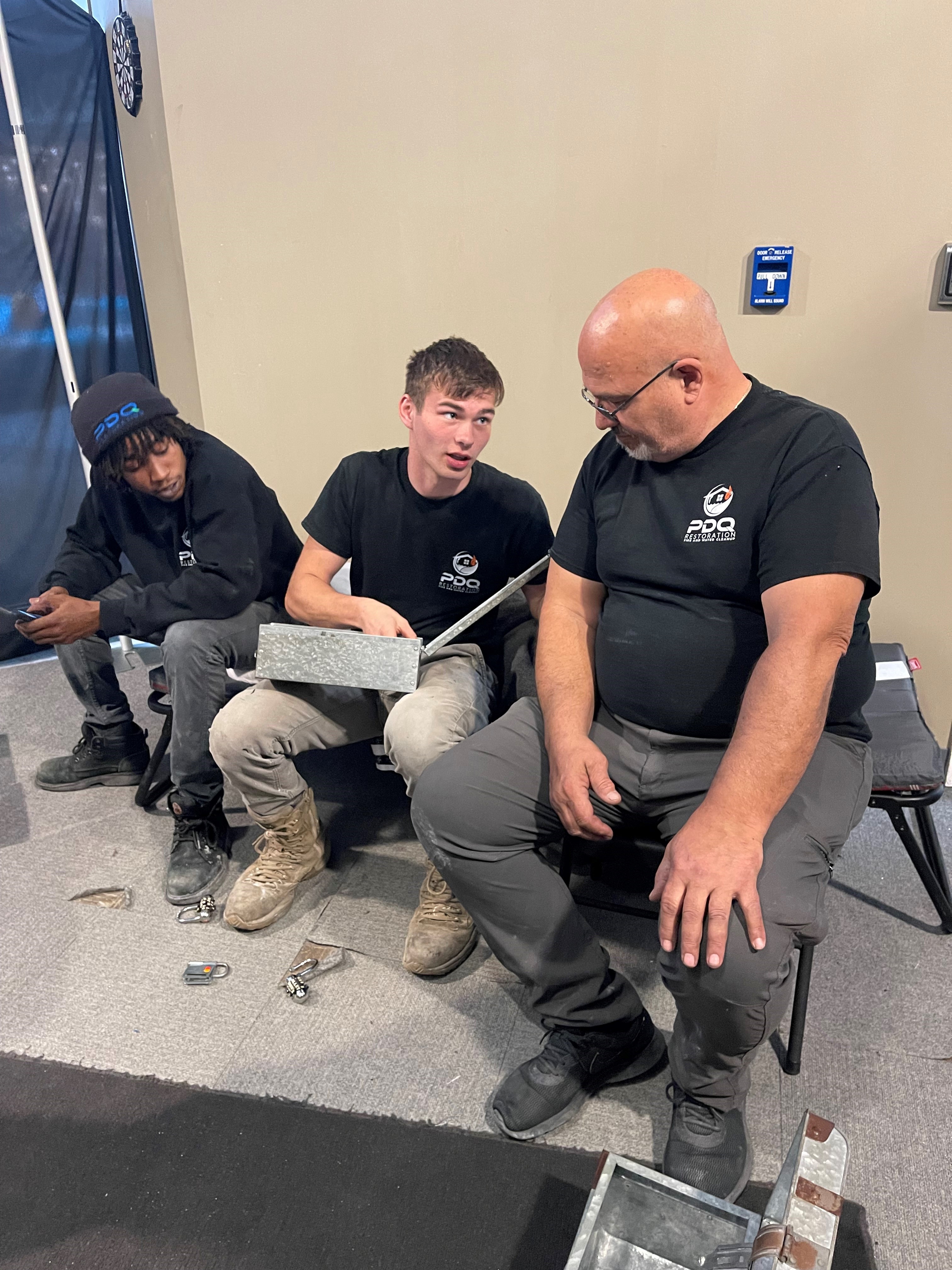

Jason W. encountered extensive water damage in his Morristown, NJ home after a sudden main water line break in the upstairs hallway saturated floors and leaked into the kitchen below. The Morristown property quickly developed wet insulation, soaked drywall, and wood floor water damage that required immediate water extraction to prevent structural deterioration. Because this was an insurance-covered loss, technicians performed moisture mapping, documentation, and detailed photo records to support the claim. Crews completed appliance leak cleanup in adjacent rooms where water had migrated beneath cabinetry and into concealed spaces. Structure drying equipment was placed throughout the Morristown residence to stabilize humidity and prevent secondary mold growth. Continuous monitoring ensured that all impacted materials in Morristown trended toward proper drying goals before demolition decisions were made.

During the extended mitigation phase, the Morristown home required targeted wall cavity drying to eliminate moisture trapped behind framing after the water pipe break. Technicians removed wet insulation, sanitized subfloors, and used drying mats to salvage portions of the damaged wood flooring. Additional inspections were performed on the HVAC discharge line to ensure no secondary leaks contributed to the loss, a common precaution in older Morristown homes. Water extraction and structure drying continued with controlled airflow and dehumidification to restore safe moisture levels throughout the building envelope. Contents affected by the saturation were inventoried and documented for the homeowner’s insurance carrier to streamline the restoration process. By the time drying goals were achieved, the Morristown property was fully stabilized and ready for reconstruction following comprehensive water damage mitigation.